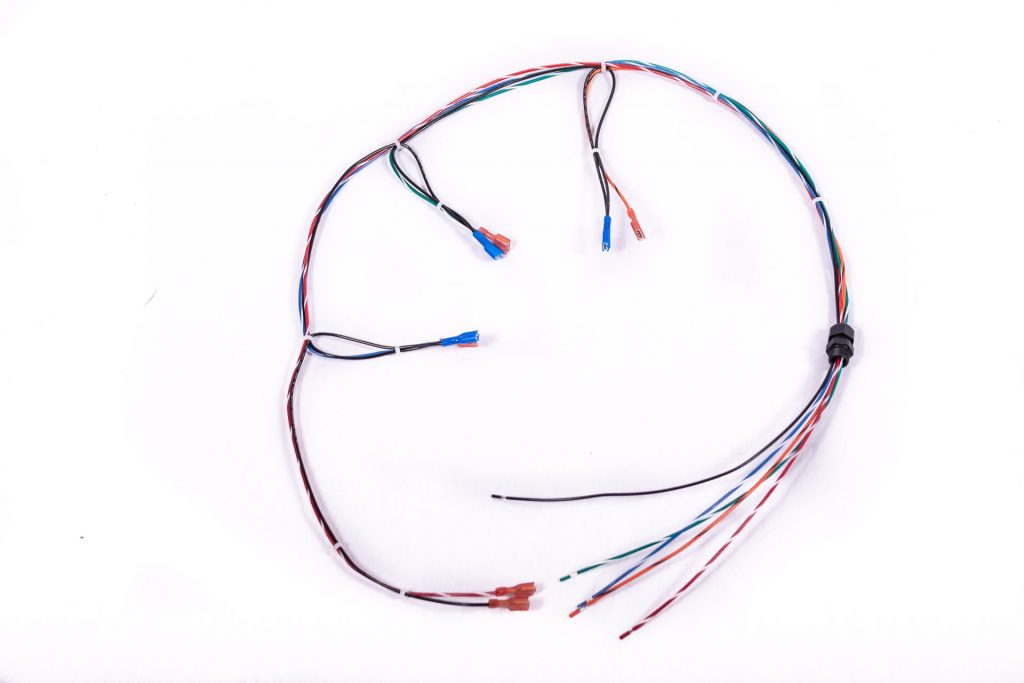

In part 2 of this 3 part series we will focus on the technology available at wire harness manufacturing facilities that can improve the design, reduce costs and create more robust assemblies. If you haven’t read part one, click here.

Many times throughout the year I am approached by prospective customers looking for a wire harness shop. It is not uncommon to have customers that lack an electrical engineer, a set of prints, a bill of material or all three. In some cases the design of the harness was developed on the manufacturing floor and no documentation was provand BOM’s.

We receive many requests throughout the year for quotations on wire harnesses. The level of detail provided for us to use to develop a quote varies from large sets of prints that include top level assembly and separate prints for all of the subcomponents to crude samples and hand drawings.

For the purposes of understanding how a wire harness shop can benefit a business requesting a quote I am going to breakdown the types of inquiries we receive into three categories.

High Level of Detail

The first category is the high level of detail. These tend to come from larger companies with engineering departments and a high level of documentation requirements. They include a top level print, a BOM with manufacturer part numbers specified and prints for subcomponents.

One of the first things that I look at when I receive the prints is the date that it was created and the revision level dates. Has the print been created recently or is it an older print? Since technology for manufacturing changes there may be an opportunity to improve the design or reduce cost if the print was created more than 2 years ago and has not been updated. These options are provided to the customer if applicable.

Mid Level of Detail

The second category is a mid-level of detail. This is most commonly what we see from the inquiries that we receive. These customers will often provide a top-level print and a BOM. Both of these will typically require clarifications due to: Missing manufacturer part numbers, prints that do not specify the lengths of wire that will allow us to create a cut sheet, outdated part numbers on components are a few examples. We address these as part of our estimating process and work with our customer to get clarifications. At Elektro Assemblies we take the extra step to find alternates to obsolete components and propose them to our customer. This saves them the time to have to research on their own time.

Some of the more common design changes that can be implemented are:

- Conversion of connector based splices to sonic welding the wire together. This eliminates components in the assembly and can improve conductivity.

- Braiding of the finished assembly vs. the use of split loom. Braiding has a minimal cost impact vs. split loom and provides better protection.

- Conversion of multicolored wire in assemblies to Black and White wire with printing on the wires to indicate the circuit. This has a significant impact on the cost of the assembly since the manufacturer of the assembly does not have to buy spools of colored wire and instead can use just black and white wires. Wire printing allows for an unlimited number of characters and is growing in popularity.

Low Level of Detail

The third category of customer provides us with a low level of detail. Information provided to us ranges from a basic print with very little detail to a sample of an assembly with no documentation. Here at Elektro Assemblies we are happy to look at these types of projects. As a contract manufacturer the design of the final product is the full responsibility of the customer but we offer assistance in coming up with a design that can be manufactured in a way that leverages the manufacturing technology we use. Once the project proceeds to manufacturing Elektro Assemblies develops a set of work instructions for the build of the assemblies. We will also develop the documentation required to program our wire processing equipment to produce the right lengths of cut wire.

These customers often benefit the most from the manufacturing technology available since they are open to creating an assembly that is fully functional and incorporates the latest in manufacturing technology.

At Elektro Assemblies we are committed to using the latest in manufacturing technology. We have virtually eliminated the need for hand tools to be used in our facility. If you have not visited a wire harness shop in the last 5 years and you are involved in the development, design, or procurement of wire harnesses you should make it a priority to schedule a visit. Aligning your design with the current capabilities of a manufacturer will result in a lower cost, higher quality, more robust product.