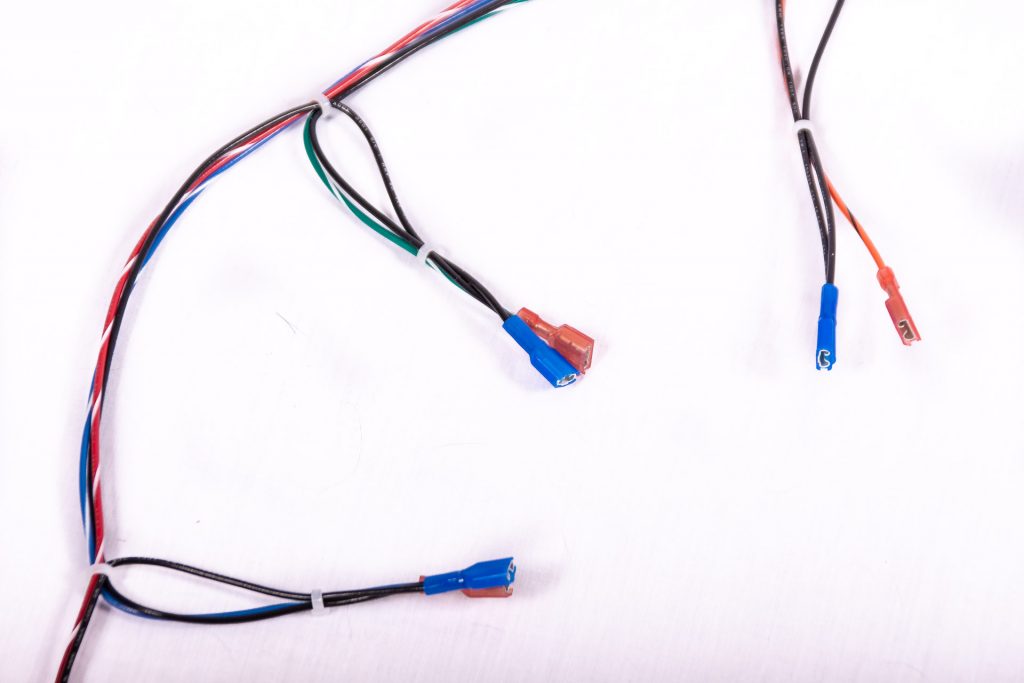

Part three of this series will focus on how to successfully transition your wire harness manufacturing from in-house to a contract manufacturer.

So, you have made the decision to look for a partner that can satisfy your demand for wire harnesses.

What next?

Step One: Assessing the supplier base

The first step in the process is to reach out to wire harness manufacturers and discuss your anticipated needs. Most oftentimes this means that you will need to provide the manufacturer with prints, BOM’s, EAU’s and MOQ’s. You will also need to verify that the supplier has the certifications you require for your finished product. Companies that maintain ISO certification provide you with the assurance that the company is maintaining business records and has processes and standards in place to be a high quality supplier. You will want to understand if the wire harness supplier adheres to, and is a member of IPC/WHMA. Members of this organization have trained staff that have completed certification showing that they understand and adhere to the industry set of standards. You might ask, “What standard are your wire harnesses built to?”. The answer should be IPC/WHMA A-620 standards. If you require a specialized standard, for example military you should ask about this as well.

Step Two: Meet with the suppliers

I can’t stress the importance of this enough. If you are serious about outsourcing, visit the supplier to review the quotes. Wire harnesses are the “nervous system” of your product. They simply must work as designed. Make the investment of time and visit several suppliers. Without a visit and the opportunity to meet the people you will be working with your decision will come down to price and lead time. These are only two parts of a long list of requirements that will need to be met to successfully transition your wire harness manufacturing. Late orders can shut off your ability to ship product.

Step Three: Select a supplier

Using all of the information you have acquired through the first two steps, select a supplier and move forward. At this point the supplier should have a full understanding of who to contact at your business so communication is clear and is routed to the appropriate party.

At Elektro Assemblies we encourage our customers to dedicate 30 minutes per week to a meeting between our company and the new customer. All stake holders from both companies are encouraged to attend these meetings. We recap progress from the last week, identify open issues and provide responses to customers questions. We conclude each meeting with a “to do’ list for the next week. Our experience has been that these meetings ensure that we are making steady progress and becoming familiar with each other’s business needs.

Step four: Assessment of performance

After your first articles have been shipped and approved and you have received a production order your supplier should schedule a meeting to review how the process went and identify opportunities to improve. This is the step that most often gets skipped. I often find that after we have completed the onboarding process our customer will say “everything is great” and will want to just move on. A face-to-face meeting with the customer often reveals that while the overall process went good, there are things that could still be done to improve. Sometimes these are minor design changes that would allow for easier manufacturing, packaging and labelling, etc. Switching from in-house manufacturing to a contract manufacturer impacts your production staff as well. Often the production staff has worked with these assemblies when they were built in-house. What do they think of the product your new supplier shipped to you? I have found that the production worker almost always has some ideas on improvements that could be made.

Sounds simple right?

We all know that onboarding a new supplier is a process that requires a lot of work and good communication. The steps I outlined above are meant to be a top-level guide to transitioning your wire harness manufacturing to a contract manufacturer. These transitions involve hundreds of emails, phone conversations and clarifications all of which take time. Working with a partner that is fast, flexible, and responsive not only improves the likelihood of success but also decreases the investment of time. At Elektro Assemblies we have made a dedicated effort to provide a seamless process that allows prospective customers to transition quickly and effectively. We pride ourselves on our speed and can usually make this transition in 6-8 weeks. We also offer a FastTrack service that allows us to take individual assemblies and build them in as little as 3 weeks. Please feel free to reach out with any questions about how to effectively transition your wire harness manufacturing. I would be happy to help.

If you are interested in learning more about what Elektro Assemblies can do for your business please give me a call. I would be happy to discuss this with you and put you in touch with contacts from recently onboarded companies that you can use as references.

For more information, read part 1 and part 2 of this series.

By Jon Bush – a business leader with over 20 years of experience growing businesses. He has worked with over one hundred business owners to improve their processes and grow sales. His experience includes purchasing, dealer networks, distribution, B2B sales, Inside and Outside Sales management. He’s worked directly with businesses that thrive and some that fail.